First Eco-Positive

Rum Production

AT EVERY STEP IN OUR PRODUCTION PROCESS, WE SELECT METHODS AND MATERIALS THAT ARE NON-EXPLOITATIVE. THIS MEANS THAT WE CHOOSE HOW WE MAKE RUM BASED NOT ONLY ON THE FLAVOR AND QUALITY BUT ON THE IMPACT OF OUR PROCESS AS WELL. WE PERSONALLY ASSURE YOU THAT WE HAVE CAREFULLY EXPLORED METHODS AND SELECTED INGREDIENTS THAT WITHSTAND RIGOROUS SCRUTINY.

01

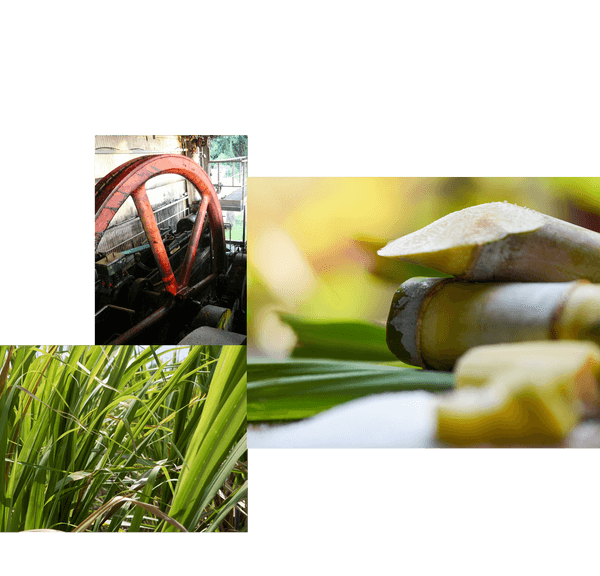

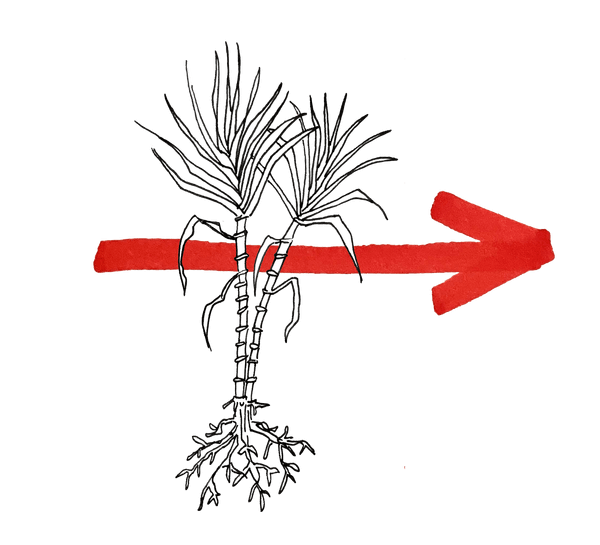

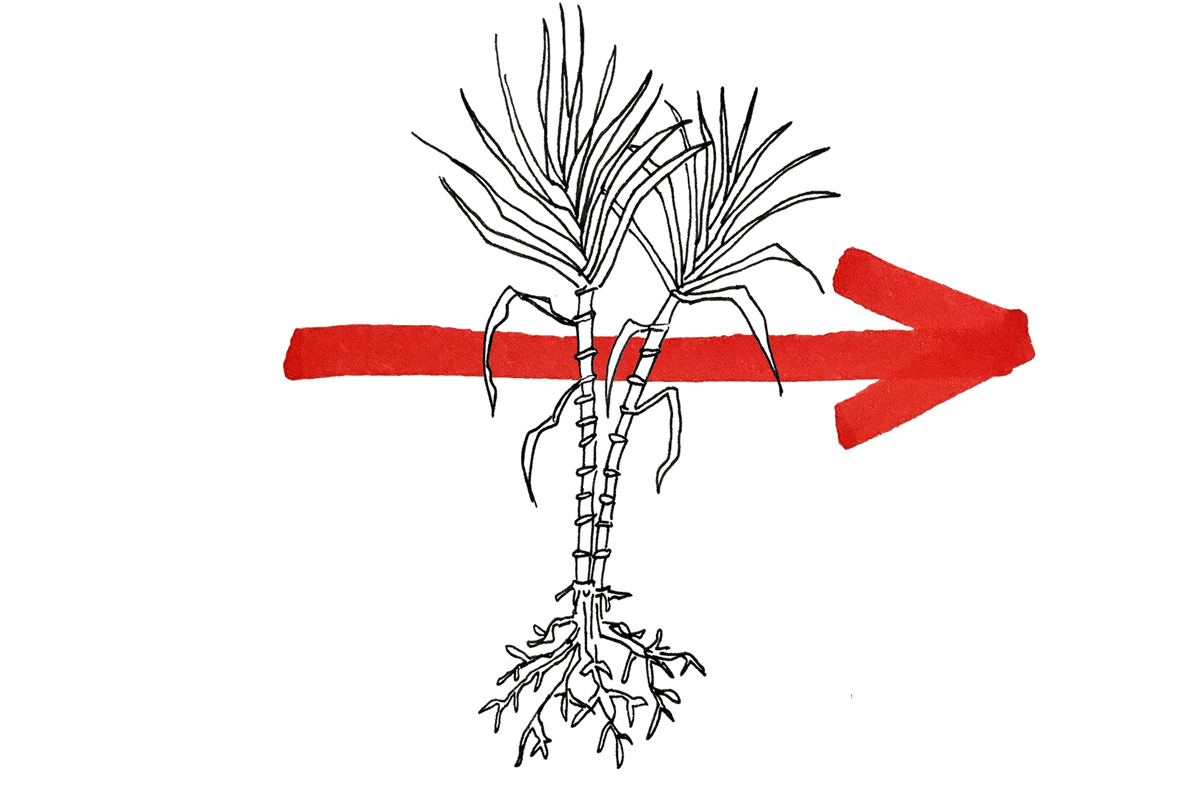

GROWING CANE

The sugarcane used in Batiste Rhum is a perennial plant that is harvested from February through July (during the dry season).

02

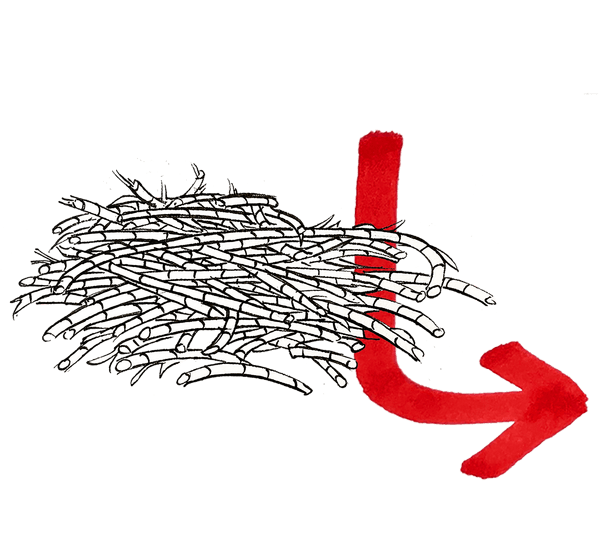

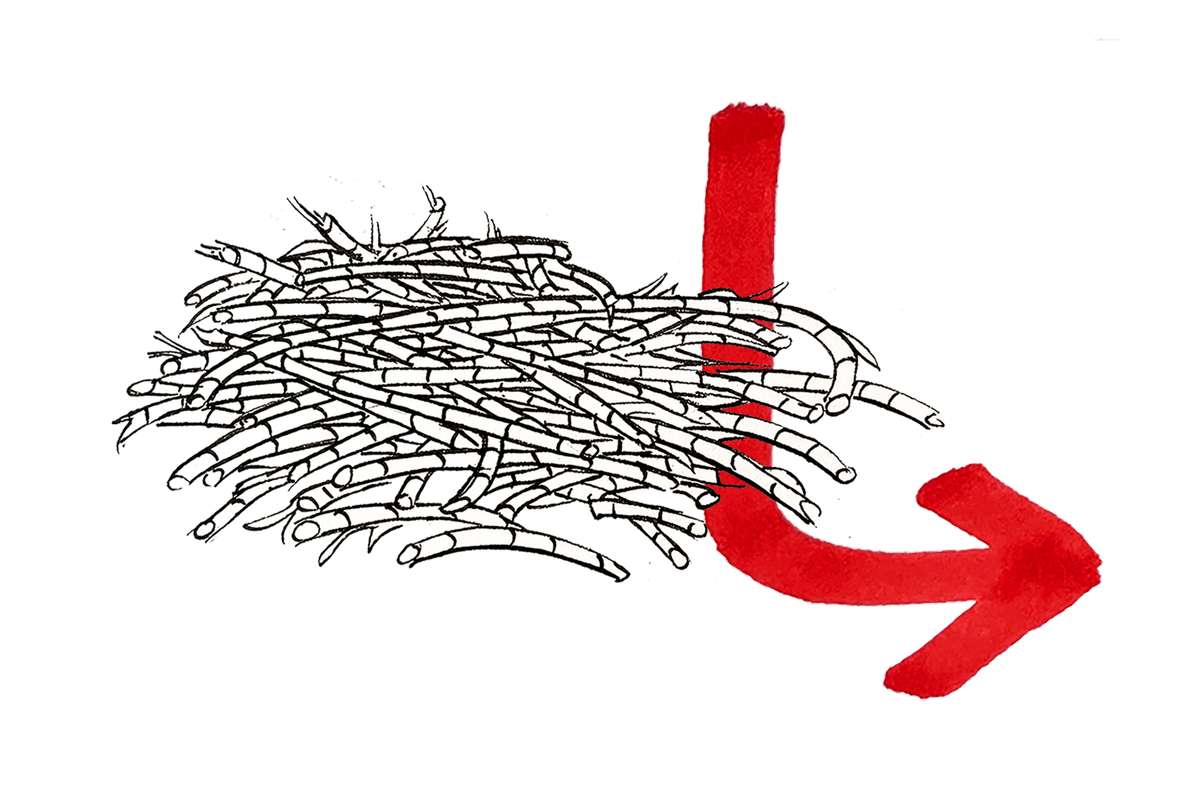

HARVESTING CANE

Each day the amount of cane that can be processed by the distillery is harvested and brought to the distillery fresh and unburnt. There are two methods for harvesting: by hand and by combine.

03

MILLING AND JUICING

The harvested cut cane is loaded into a large hopper that feeds a solar-powered electric mill, which extracts the juice and feeds the waste into the boiler. The juice moves directly into clean stainless fermentation tanks.

04

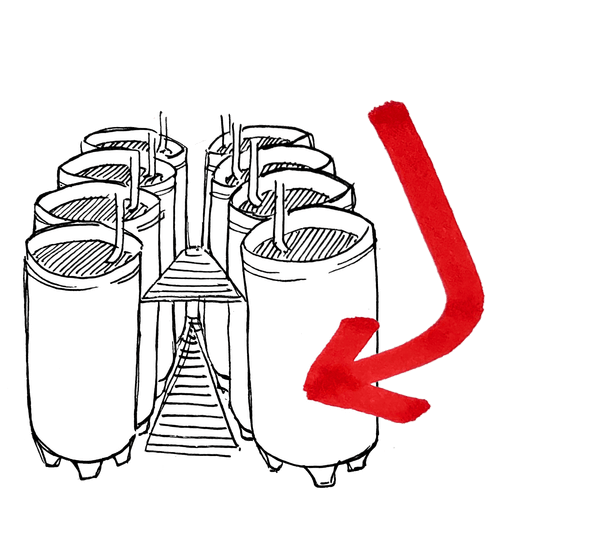

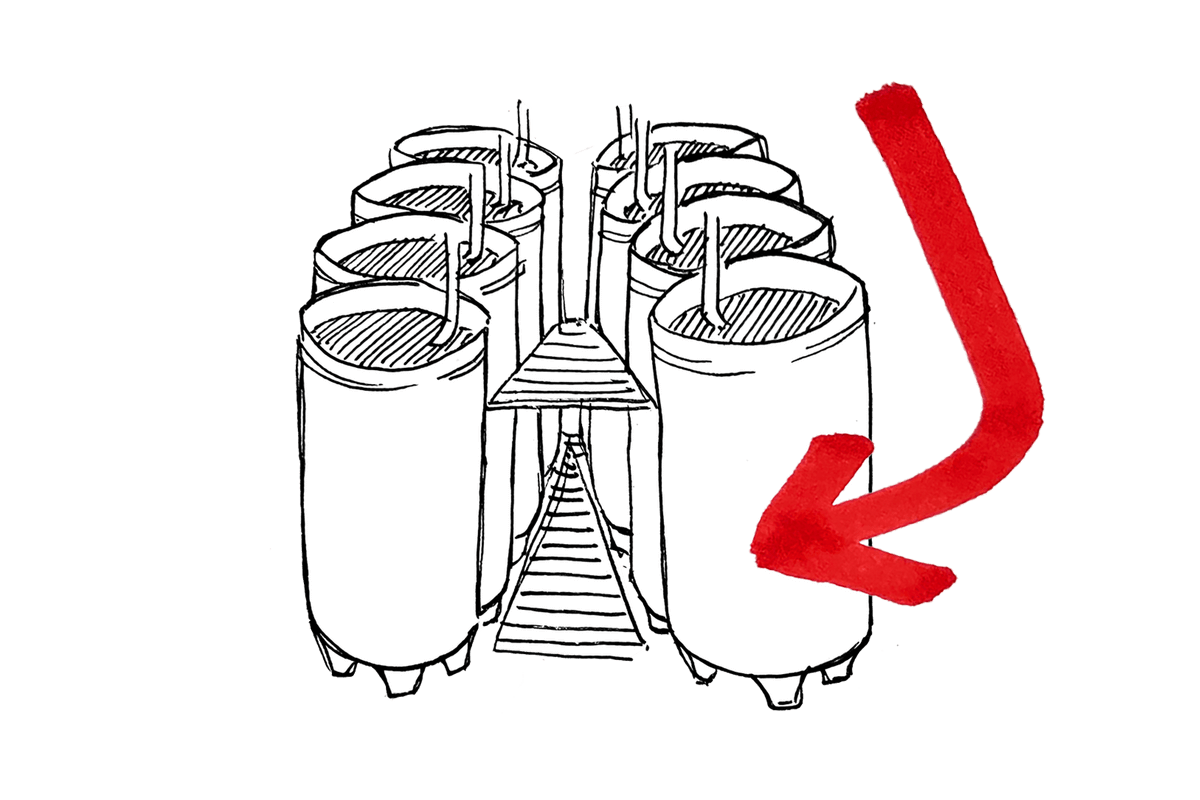

FERMENTATION

The fresh juice receives brewers yeast and ferments until reaching a 5% alcohol level before moving through distillation. Each batch is controlled and monitored for yeast. Any mold or bacteria found in the ferment during regular lab analysis causes the batch to stop.

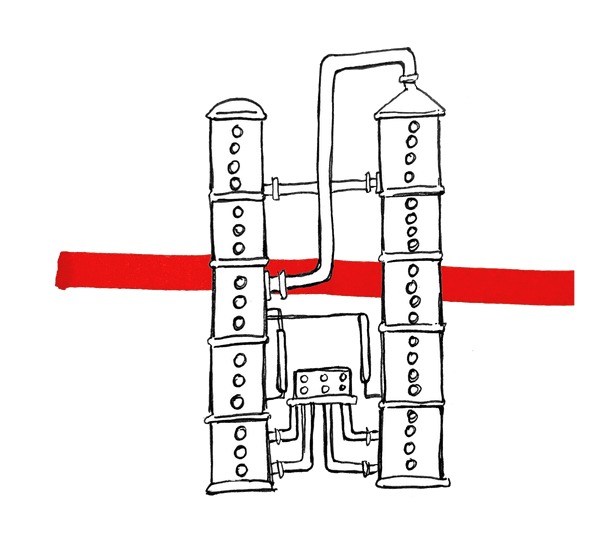

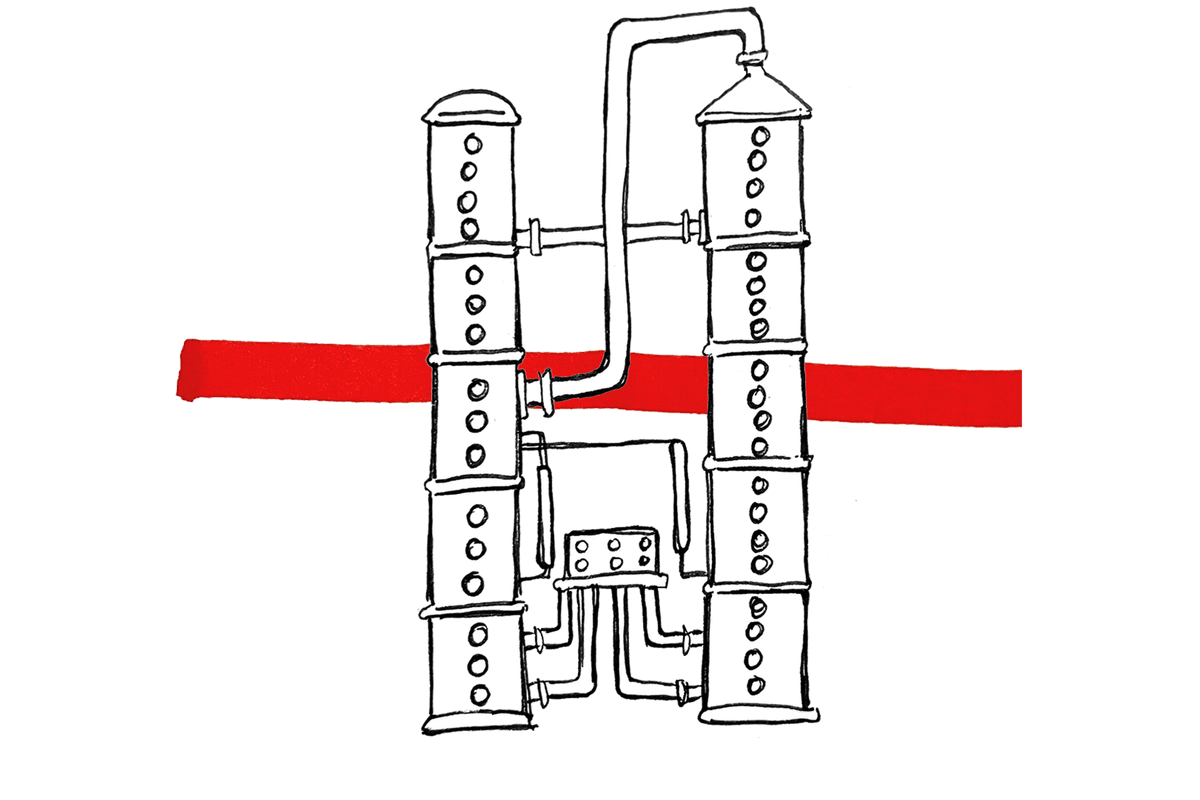

05

DISTILLATION

Two steam heated column stills convert the sugar cane wine into 78% ABV rhum agricole distillate.

06

SHIPPING

We pack the rhum distillate into IBC tanks for ocean freight from Marie Galante to Napa.

07

AGING

Our Gold and Reserve rums are gently aged in former American Rye Whiskey barrels for at least 6 months and at least 24 months, respectively.

08

PACKAGING

We select bottles, labels, and tops that are made from 100% recycled materials or have been certified as sustainable forest products.

09

BOTTLING

Prior to bottling Batiste Rhum receives purified water.

BECAUSE OF THE C02 ABSORPTIVE QUALITIES OF GROWING SUGAR CANE, BATISTE RHUM HAS A BUILT-IN OFFSET THAT WE SPEND DOWN IN OUR PRODUCTION. THIRD-PARTY ANALYSIS HAS VERIFIED THAT WITH ALL OUR PRODUCTION INPUTS, BATISTE RHUM HAS A NET NEGATIVE CO2 EMISSION OF 980G PER BOTTLE EX WAREHOUSE IN NAPA, CA. IN OTHER WORDS, OUR PRODUCTION CHOICES LET US HAVE A VERY LIGHT ENVIRONMENTAL FOOTPRINT WITHOUT RELYING ON PURCHASED OFFSETS.